Cooling tower water loss calculation

Evaporation loss + Water drain/blowdown loss + Drift loss = Total water loss in cooling tower

Three ways water loss happens in a cooling tower.

- Evaporation loss

- Water drain/Blowdown loss

- Drift loss

We will calculate water loss for these three ways and finally get the total loss.

Total loss = (evaporation loss + Water drain/Blow down loss + Drift loss)

These calculations are very basic. So, it’s obvious that these calculations will be very easy. We will discuss this by following the easiest way.

Evaporation loss:

You need to have the following information to calculate the evaporation loss.

- Capacity of your chiller (In ton)

- Δt = ?

- water circulation flow rate of the evaporator.

- Water circulation flow rate of the cooling tower.

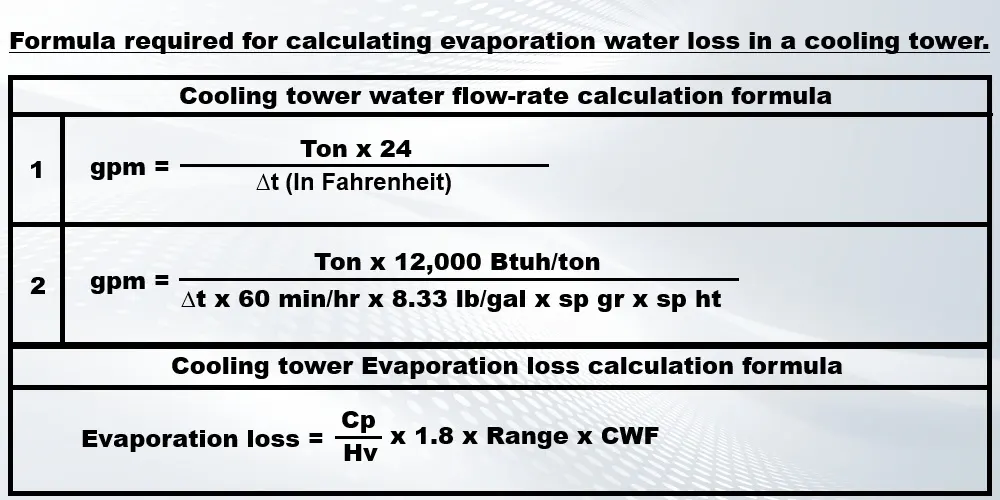

These formulas will be used to calculate the evaporation loss and water flow circulation. As you can see, there are two formulas for water circulation flow calculation. The 2nd one is with more details for better understanding. But during water circulation flow calculation, we will use the 1st formula (GPM = Ton x 24 / Δt).

Example:

Let’s calculate evaporation loss for a 300 Ton system.

Δt = we know that, from the evaporator, 6°C chilled water comes out after heat exchange, 12°C hot water turns back to the evaporator. Here, Δt = (12-6) = 6°C = 10.80°F

water circulation flow rate of the evaporator:

- Gpm = Ton x 24 / Δt

- 300 x 24 / 10.80

- 666.67 gpm

So, the water circulation flow rate of the evaporator is 666.67 gallons per minute.

water circulation flow rate of the cooling tower/condenser:

Cooling tower water flow rate = (Evaporator water flow rate x 1.20) [20% extra]

Δt will be the same for both the evaporator and cooling tower loop. In this case, if the evaporator water flow rate is 666.67 gallons per minute.

Cooling tower water flow rate also needs to be 666.67 gallons per minute. But in reality, it doesn’t happen. As we know, the cooling tower is an open-loop system. Dust can easily be added to the water here. For that reason, as per ASHRA standard, the condenser/cooling tower water flow rate will be 20% moreThe than the evaporator water flow rate.

So, if we add 20% extra with 666.67 gpm

circulation flow rate of the cooling tower/condenser will be

- (666.67 x 1.20)

- 800 gpm

So, the cooling tower water flow rate is 800 gallons per minute.

Now, we get all of our required data:

- Capacity of the system: 300 Ton

- Range = (Hot water temperature – cold water temperature) = 6°C (as we know that the Δt = 6°C)

- Water circulation flow rate of the evaporator = 666.67 gpm

- Water circulation flow rate of the cooling tower/ condenser = 800 gpm

Evaporation loss will be:

Cp = Specific heat of water = 4.184 kJ/(kg.°C)

Hv = Lantern heat of vaporization = 2260 KJ/KG

- Cp/Hv =0.00085

CWF (Calculated water flow) = 800 gpm

- CWF = 3032 lpm (gallons per minute to liters per minute conversion)

We know,

- Evaporation loss = Cp/Hv X 1.8 X Range x CWF [1.8 is conversion constant]

- 0.00085 X 1.8 X 6 X 3032

- 27.84 Liter per minute (Lpm)

Through evaporation, 27.84 liters of water are lost per minute.

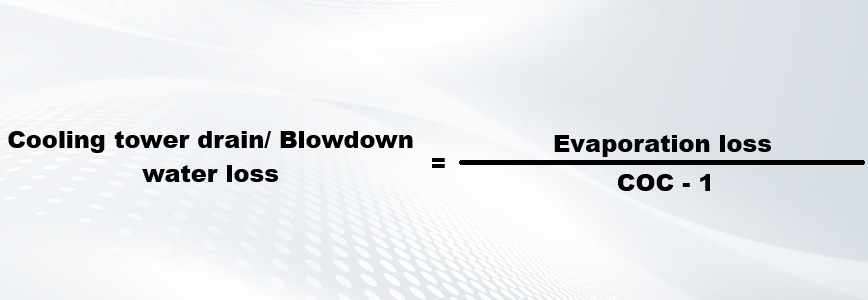

Water drain/Blowdown loss:

What is COC (Cycle of concentration)?

In cooling tower water, there will be Fe, Mg, Ca, etc, minerals. Because of this, the cooling tower water is highly conductive compared to clean water.

The conductivity ratio between cooling tower water and makeup water or newly added water is called COC.

COC = Conductivity of cooling tower water / Conductivity of makeup water

- What if the conductivity of cooling tower water = 1

- And the conductivity of Makeup water = 1

- COC = 1/1 = 1

If both of them are the same, that means cooling tower water is on highest clean form. Well this never happens. I showed you just as an example.

The conductivity of cooling tower water will always be higher than the makeup water. The question is how much difference between cooling tower & makeup water is acceptable.

The answer is 1.8

If the COC is higher than 1.8, that’s a sign that your cooling tower needs a cleaning service.

Let’s assume the COC is 1.8 (But during practical calculation, find out the COC & use the actual data)

COC is 1.8

- Drain / Blowdown loss = Evaporation Loss / COC + 1

- 27.84 / 1.8-1

- 34.8 Lpm

So, 34.8 liter water loss happen per minute through Water drain/Blowdown loss.

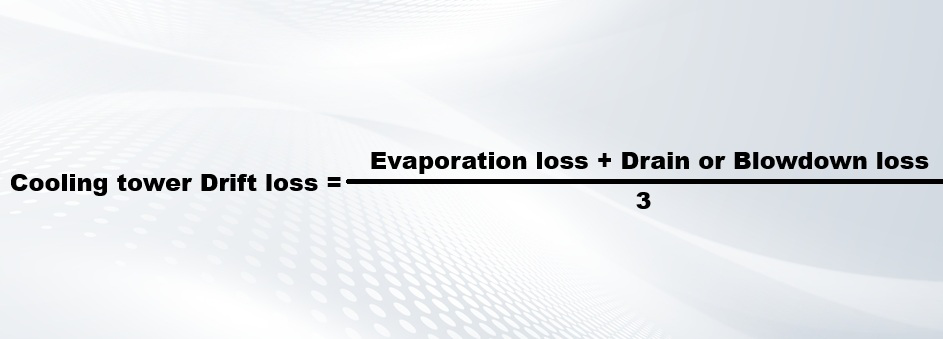

Drift loss:

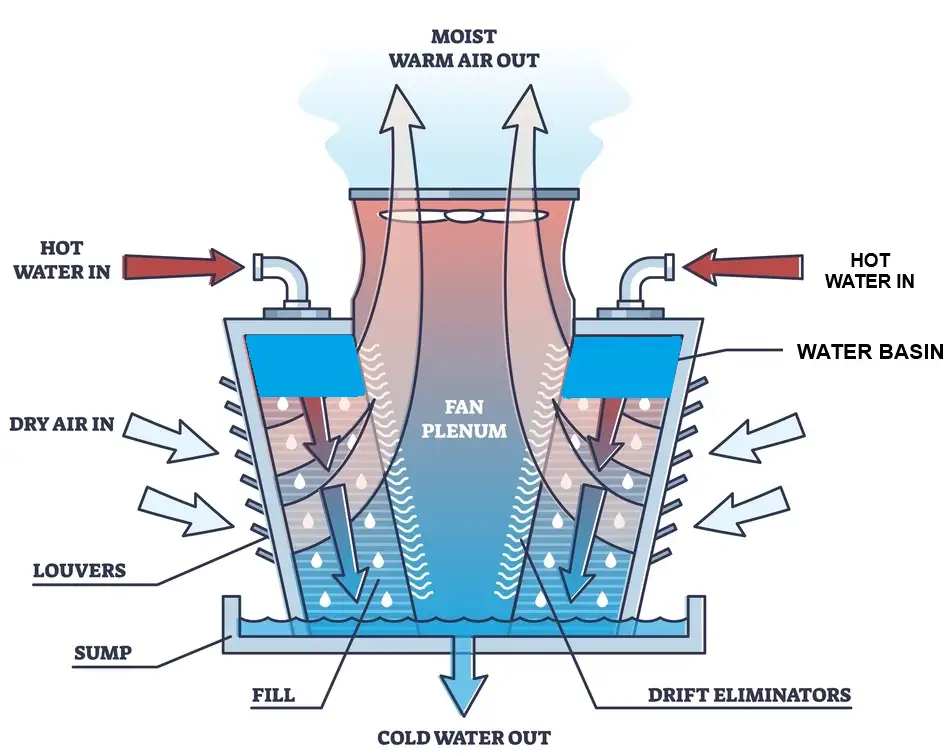

When the fan is running, due to high airflow, small water droplets escape from the cooling tower. Here we will calculate this water loss.

Nowadays almost all types of cooling towers have draft loss protection. As you can see in the picture, small drop of water stuck here & this is how the drift eliminator reduces water loss.

- Drift loss = (Evaporation loss + Drain loss or blowdown loss) / 3

- (27.84 + 34.8) / 3

- 20.88 Lpm

20.88 liter water loss per minutes happen through drift loss

- Total water loss for cooling tower = (Evaporation loss + Water drain/Blow down loss + Drift loss)

- 27.84+34.8+20.88

- 83.52 Lpm

So, 83.52 liters of water are lost per minute in this cooling tower.

This is the minimum water loss for a cooling tower. I hope I was able to explain everything as easily as possible. So, practice it by yourself.