Desiccant dehumidifier working principle

A dehumidifier is used to control the humidity of the air. Depending on different areas and places the humidity requirement is different. Desiccant dehumidifier is used where someone wants maximum control over humidity. If someone wants to reduce the humidity by 50% or less then, he/she must choose a desiccant-type dehumidifier. Unlike refrigerant type, It can offer more efficiency, comfort and better control. It can also be used with HVAC systems like AHU and ducted indoor units.

I have worked with desiccant dehumidifiers on the industrial level. Here I will explain

- the working process of desiccant dehumidifier.

- I will share a design of one of my projects that I completed before and will explain how it works in a practical project.

- Installation process of a desiccant dehumidifier.

- When should you choose a desiccant dehumidifier over a refrigerant-type dehumidifier?

Working process of a desiccant dehumidifier:

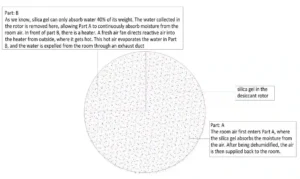

The main part of a desiccant dehumidifier is the Desiccant rotor. Silicon gel is present in the desiccant rotor. The indoor air goes through the desiccant rotor, the silicon gel of the rotor absorbs the moisture from the air and returns it to the room air. Basically, a desiccant dehumidifier uses silicon gel to absorb moisture from the air. Silicon gel can absorb water up to 40% of its weight.

The desiccant rotor in the dehumidifier rotates slowly. As shown in the picture, the desiccant rotor has two parts: Part A absorbs moisture from the room air, and Part B evaporates the moisture so the collected water can be exhausted outside.

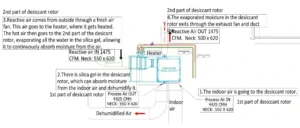

As you can see in the picture, the desiccant dehumidifier has four air inlet and outlet lines. Room air enters the dehumidifier through the first line and passes to Part A of the desiccant rotor, where the silicon gel on the rotor absorbs the moisture from the air. This dehumidified air returns to the room through the second line of the dehumidifier.

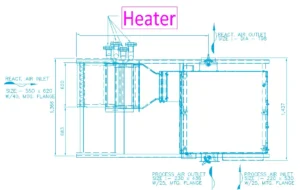

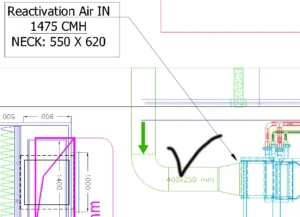

The third and fourth lines work with Part B of the desiccant rotor. A fresh air line is connected to the third line, where a fresh air fan draws in reactive air from outside. This air passes through a heater in the dehumidifier, becoming hot. The hot air flows through Part B of the desiccant rotor and evaporates the collected water.

The fourth line is an exhaust line with an exhaust fan, which expels the evaporated air outside.

The heater in the desiccant dehumidifier can be an electrical heater, but in the industries level, waste hot water or steam also can be used for the heater of a desiccant dehumidifier. Which can make your dehumidifier very very efficient. In the below example/Design, you will see how a desiccant dehumidifier heater can run with industrial wastage steam and work with an AHU.

Practical Example and Design of Desiccant Dehumidifier Project:

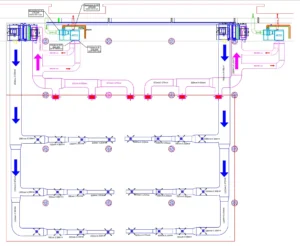

It was a Chips factory. Where the humidity requirement was less than 50%. We use 2 nos “Fisair, (Model: DFRA-0900V)” desiccant dehumidifiers, which are working with the Existing 2 nos AHU in the place. And the heater of the Dehumidifier is running by using the wastage steam of the factory.

HVAC Drawing: Akij Bakers Chips Zone Dehumidifier-Layout_11zon

Here is the design of the Project. I suggest you read the design first, so that when I explain the working method then you can easily understand everything. If you are new or Can’t understand the design then don’t worry, stay with me. I will try to explain everything as easily as possible so that everyone can understand it.

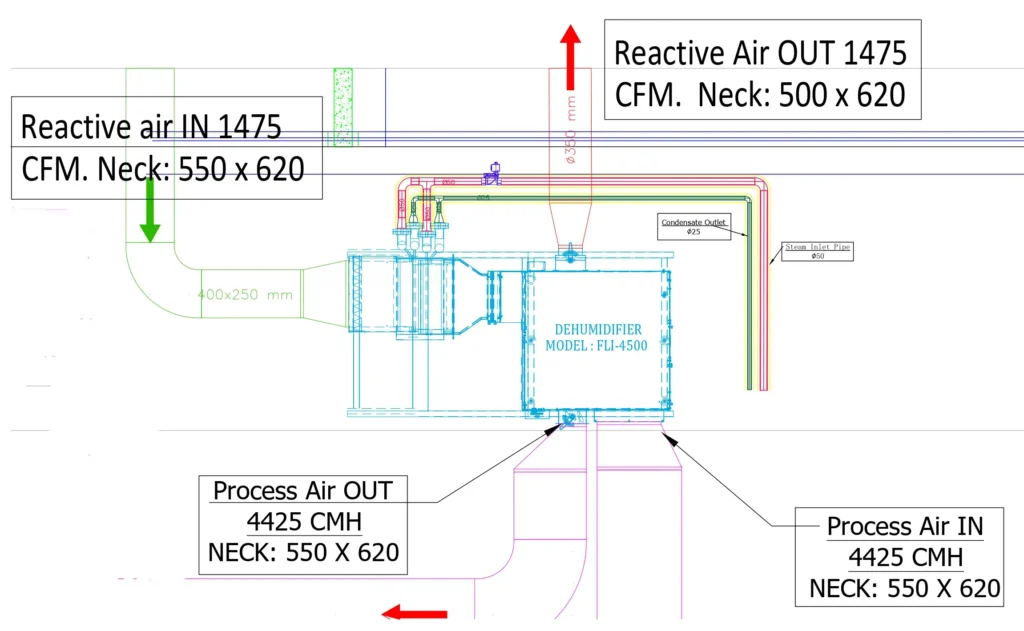

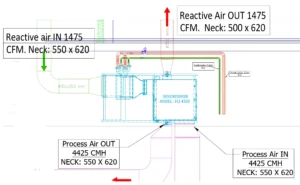

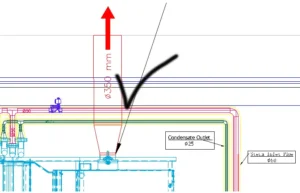

As you can see in the design there are 2 duct lines for process air in and out. And the other 2 lines are for Reactive air in and out.

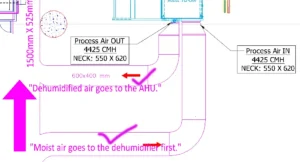

Process air/ Moisture air goes to the Dehumidifier and after the desiccant rotor absorbs the moisture from the process air (indoor air). And by the outline, this processed air goes to the AHU.

The AHU cooled this air as per requirement and by supply duct line this process cooled air supplied all over the room.

The heater in front of the desiccant rotor here, it’s not any kind of electrical heater. Here industrial wastage steam has been used.

You can see the steam inline and outline in the design. This makes it very efficient in terms of electricity consumption. The heater is important to remove stack water. As we know, the silicon gel in the desiccant rotor only can absorb water 40% compared to its weight. So if we don’t remove the water from the desiccant rotor then the dehumidifier will not be able to absorb moisture from the room air.

Here reactive air/Fresh air/ Moisture air comes to the heater first, the heater makes it superheated. This superheated air goes through the part of the desiccant dehumidifier. Where the water stacks. This hot air evaporated the stack water from the desiccant rotor so that the desiccant rotor constantly absorbed the water.

This evaporated air goes out by this exhaust duct line. I hope you get it now. That’s how it works.

Installation process of a desiccant dehumidifier:

In refrigerant dehumidifiers, people don’t need to think much about the installation process. Because then you just connect it to the electricity and set the drain line, That’s it. But when it comes to desiccant dehumidifiers, there is so much to do.

- First hanging the Desiccant dehumidifier.

- You need to do duct (making, fabrication and hanging) work.

- Use canvas cloth for duct and machine connection.

- Complete the electrical connection.

- If the Heater is run with industrial steam or hot water, then you should complete the MS pipe work with proper insulation and jacketing.

When/why you should choose desiccant dehumidifier:

- If the place you want to control the humidity is very cold, then you should go for a desiccant dehumidifier.

- If you want to reduce the humidity 50% or more then you should choose it.

- It can run at a very low level.

- At An industrial level. For example chip or dried fruit factories have specific humidity requirements. Even a small change in humidity can ruin an entire production. Dehumidifiers ensure the air remains dry and your favorite snacks stay crisp and fresh. Without a dehumidifier, maintaining the crispness of these products is impossible.

- In the pharmaceutical area.

- It can be used for storing important documents, expensive equipment, antique artworks, etc. They protect these items from moisture damage.

- Chemical industry.

- Paint factory. ETC

There are so many more areas to use desiccant dehumidifiers. In commercial space, you don’t need to choose a desiccant dehumidifier. Because in the house or garage area. The humidity control requirement is not that high.

I hope this blog helps you to learn about desiccant dehumidifiers. But I personally suggest you watch some YouTube animated videos about the desiccant dehumidifier working process, then things will be much more clear to you.