The working principle of the Vapor Absorption Chiller

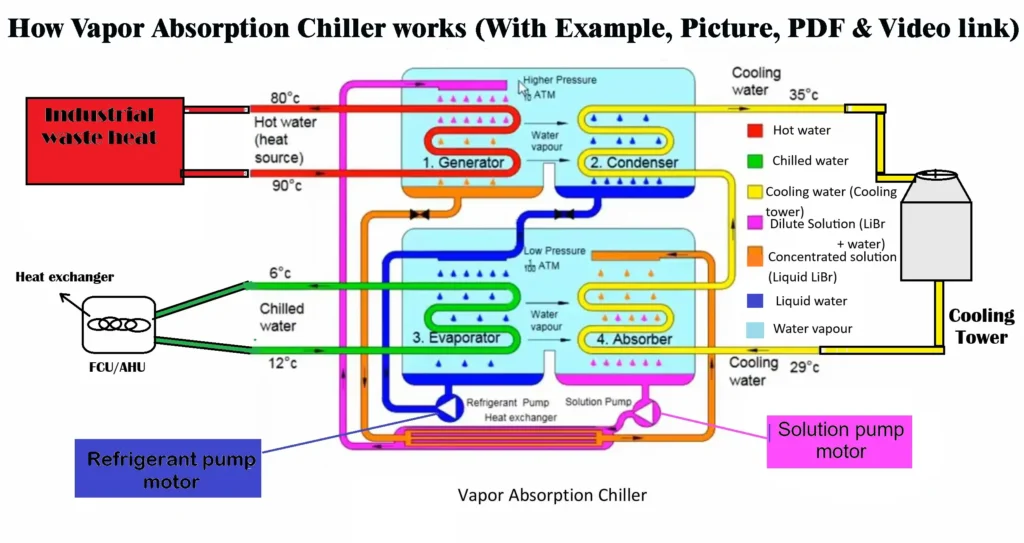

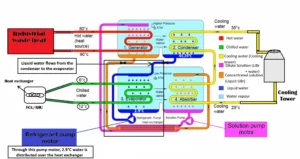

Absorption chiller operates with hot water. In industrial areas, when there is a source of waste heat, a Vapor Absorption chiller will be a perfect choice because it will be very efficient compared to other chillers. The working principle of a vapor absorption chiller is completely different compared to the other chillers. It is nothing but a game of lithium bromide (LiBr) & water (H2O) Solution. There are two parts of it, high pressure chamber (Generator & Condenser) and Low pressure chamber (Evaporator & Absorber). Before I start to explain all the details, here is some data that you need to know before understanding the working principle.

When the atmospheric pressure is 1:

1. The melting point of water is 0°C and the boiling point of water is 100°C.

2. The melting point of 100% Lithium bromide (LiBr) is 550°C and the Boiling point is 1267°C.

3. The melting point of 40% Lithium bromide (LiBr) is -3.7°C and the Boiling point is 270°C.

When the atmospheric pressure is 0.1:

- The boiling point of water is 44.24°C

When the atmospheric pressure is 0.01:

- The boiling point of water is 2.9°C

In this blog, we will explain

- High pressure chamber. (Generator & Condenser)

- Low pressure chamber. (Evaporator & Absorber)

- Cooling tower

- Issues that can happen with Lithium Bromide (LiBr)

- Attached data sheet & video link to learn more about the Vapor absorption chiller.

High pressure chamber. (Generator & Condenser):

This part in the picture is called a high pressure chamber. Generator and Condenser both are part of a high pressure chamber. Here, the atmospheric pressure is 0.1.

This part has two heat exchangers and two pots for collecting liquid water and liquid lithium bromide (LiBr). At the top of this part, you can see a vacuum pump. These vacuum pumps create 0.1 ATM pressure in this area. After the vacuum pump creates the 0.1 ATM pressure, it is the condenser’s responsibility to maintain this 0.1 ATM pressure. Let’s explore what’s happening in the Generator and Condenser.

Generator:

In the picture you can see waste hot water going through the heat exchanger. Remember in HVAC hot water temperature will be 60°C or more. Here from the waste heat source 90°C hot water enters the heat exchanger and returns to 80°C.

We will use Lithium bromide (LiBr) & Water (H2O) solutions here. The solution will be in a 40-60 ratio, depending on the manufacturer. Here we are using a 40% LiBr and 60% water solution.

If you read the picture, then you will see the liquid solution (LiBr + H2O) is dropping over the heat exchanger.

As I mentioned before, in this area the atmospheric pressure is 0.1, And In 0.1 ATM pressure the boiling point of water is 100°C & the Boiling point of 40% Lithium bromide (LiBr) is 270°C.

So, water gets evaporated here and below there is a pot where the liquid Lithium Bromide (LiBr) starts accumulating.

Upside of the Generator there is a line, through this line evaporated H2O goes to the Condenser side.

Condenser:

It’s Condencer’s responsibility to maintain the 0.1 ATM pressure in a low pressure area, here you will know why.

When the water evaporates, it’s obvious that the pressure will get higher, for example imagine a pressure cooker. When the water in the pressure cooker evaporated then the pressure increased.

In the image there is a heat exchanger, from the cooling tower cold water entering the heat exchanger. Because of that, condensation happens and the H2O converts into the liquid form again. This is because of the condenser, 0.1 ATM pressure is maintained in this High pressure chamber. But if, because of any technical failure condenser doesn’t work, then the vacuum pump will do the work.

In this part the water temperature is 44.24°C because when the atmospheric pressure is 0.1, the boiling point of water is 44.24°C. Well, from the pot liquid water goes to the Low pressure chamber (Evaporator).

Low pressure chamber. (Evaporator & Absorber):

This part in the picture is called a low pressure chamber. The evaporator & Absorber both are part of a high pressure chamber. The atmospheric pressure of the low pressure chamber is (0.01).

You can see there are two heat exchangers and two pots for collecting liquid water and liquid LiBr in this part. At the top of this part, you can see that there are vacuum pumps; these vacuum pumps create 0.01 ATM pressure in this area. After the vacuum pump creates the 0.01 ATM pressure, it is the Absorber’s responsibility to maintain this 0.01 ATM pressure. Let’s explore what’s happening on the Evaporator & Absorber.

Evaporator:

In the picture, you can clearly see there is a heat exchanger on the evaporator. This heat exchanger directly works with IDU (Indoor Unit) like FCU, AHU and RTU machines to make your place cool.

In an evaporator, the pressure is very low (0.01 ATM). For that reason, here the boiling point of water is 2.9°C. That means if the temp of water is more than 2.9°C, then it will convert into a gaseous form of water.

As you can see in the picture, from the condenser 44.24°C water is coming to the Evaporator (low pressure chamber) where the boiling point of water is 2.9°C. For that reason, 44.24°C water will instantly change its temperature to 2.9°C, and a very small part of it will convert to gaseous form. With a motor, this 2.9°C cold water will spray over the heat exchanger.

As per the AHR guideline, from the FCU 12°C water will come to the heat exchanger and after 2.9°C cold water is spread over the heat exchanger, 6°C water will return to the FCU.

In this process, the water inside the Evaporator will turn into a gaseous form. If the water converts into a gaseous form, then the pressure will increase. Absorber will maintain this situation by converting them to liquid again. Upside of the Evaporator, there is a line through this line gaseous or evaporated H2O goes to the Absorber side.

Absorber:

Lithium bromide plays the role of absorber here. We know that lithium bromide can easily absorb water, as you can see in the picture that from the Generator, the liquid lithium bromide is coming to the Absorber and sprayed over this part. During this process, Lithium bromide (LiBr) absorbs all the gaseous H2O and becomes a solution of LiBr + Water. This water & lithium bromide solution goes to the Generator through a pipeline line and the whole process runs this way from the start again.

There is one thing, the heat exchanger you see in the Absorber section has nothing to do with the process that happens in the Absorber. It is related to the cooling tower. Here are the details about it.

Cooling tower:

A cooling tower works with the condenser. Without a cooling tower water will not convert into liquid form in the condenser area. In the picture as you can see, the Hot water is coming from the condenser. The cooling tower makes this water a little bit cold, then this water goes to the heat exchanger of the Absorber, because here the temperature is 2.9°C. So, it gets cooler before entering the condenser.

Issues that can happen with Lithium Bromide (LiBr):

Lithium bromide must be maintained at a specific temperature. Otherwise, it will crystallize like ice. When the temperature is less than 35°C, LiBr will crystallize, it depends on the purity & variant of the LiBr. If it gets crystallized, then it does not melt anymore. You can see in the image that to prevent this issue, when Lithium bromide (LiBr) & water solution shift the Absorber to the Generator, in the middle of it there is a heat exchanger that maintains the temperature. Because of this heat exchanger, lithium bromide doesn’t crystallize.

PDF to learn more about Vapor Absorption Chiller:

Video Link to Learn More about Vapor Absorption Chiller:

https://drive.google.com/file/d/1oOZjhpsvkZHwHELcIou79KLpFjJUlrKw/view?usp=drive_link