How does a vapor-compression water-cooled chiller work

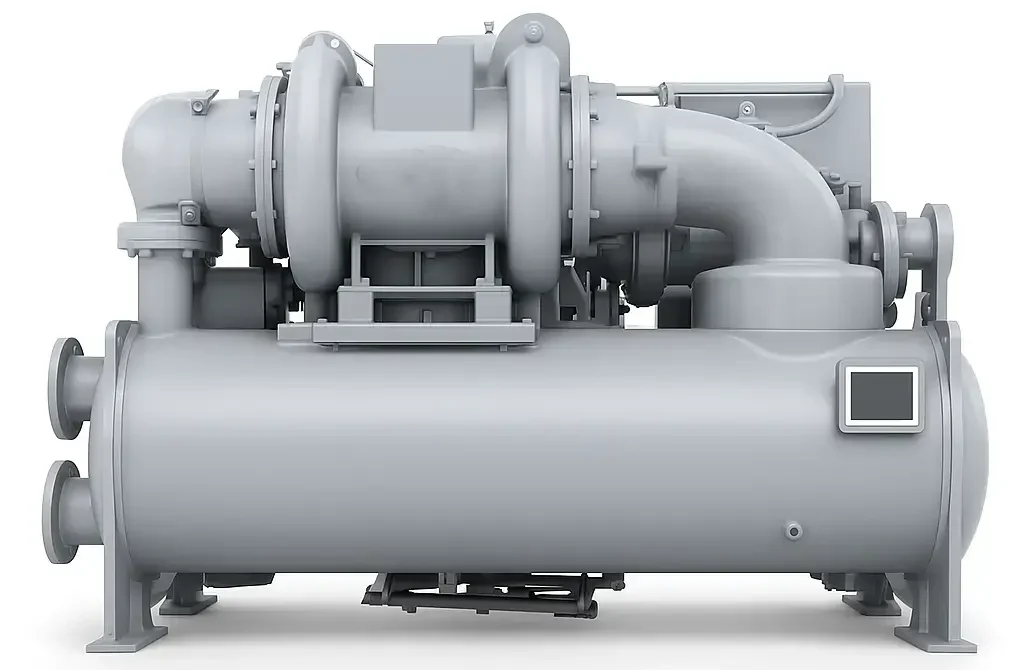

Vapor compression water-cooled chillers are known for their reliability & efficiency. Water-cooled chillers are 10 to 15 years more reliable than air-cooled chillers.

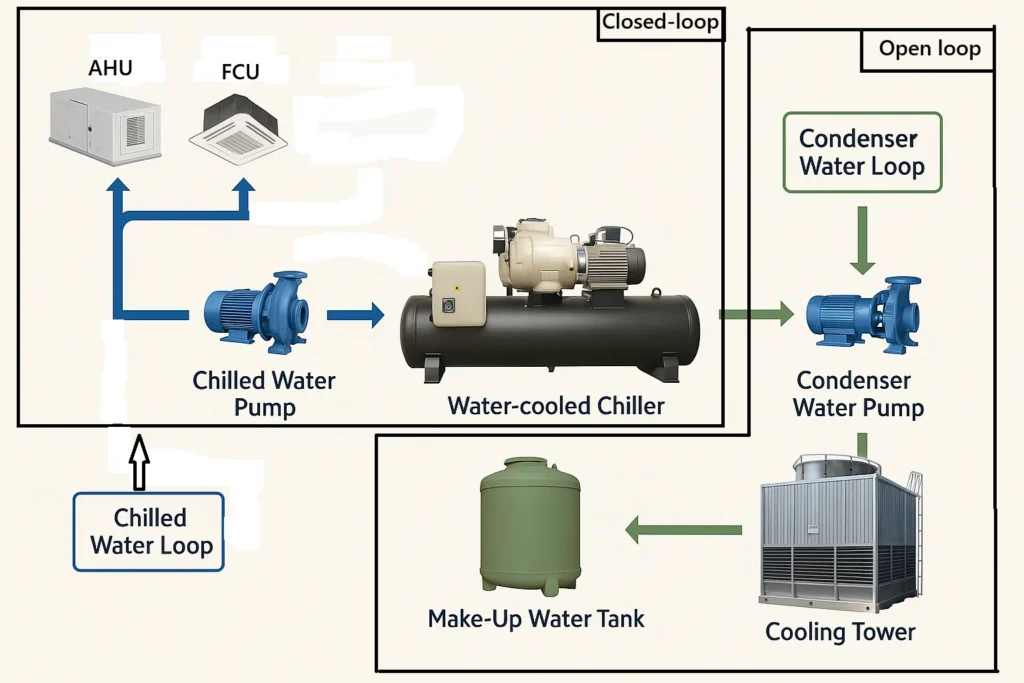

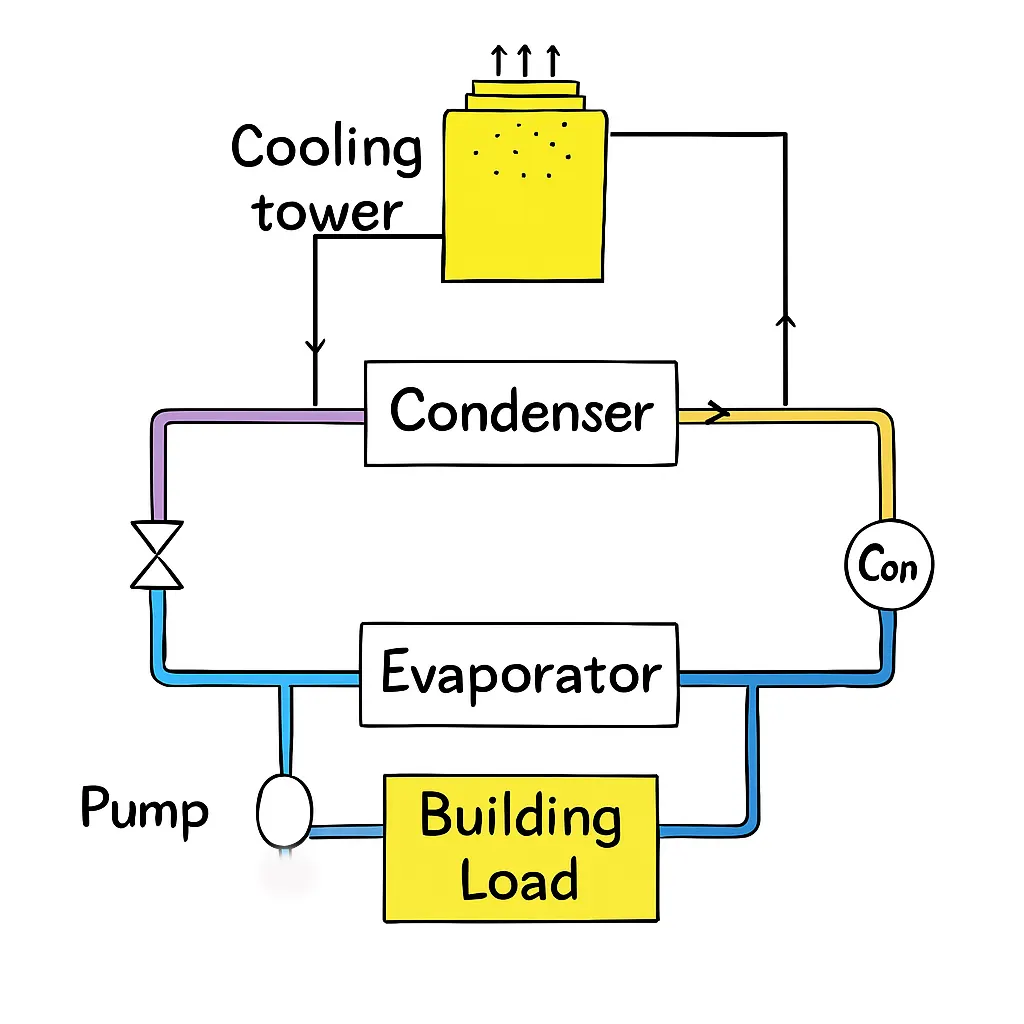

This is the picture of how the chilled water system works. In the image, I have described the closed loop and open loop.

Close loop:

- Chiller.

- Pumps

- FCU, RTU, AHU

Open loop:

- Cooling tower

- Make-up water tank.

- Pump

The cooling tower is open loop because here water gets cooled by a high-speed blower fan. For that reason, water evaporates, and also dust can easily enter here, and through the drain water some water gets wasted. When the water level decreases, the make-up water tank fulfills the required water level requirement in the cooling tower.

Let’s talk about the open-loop system. First, I will explain the entire water-cooled chiller, covering the closed-loop system. And then I will share a practical example of it getting installed and working in a building.

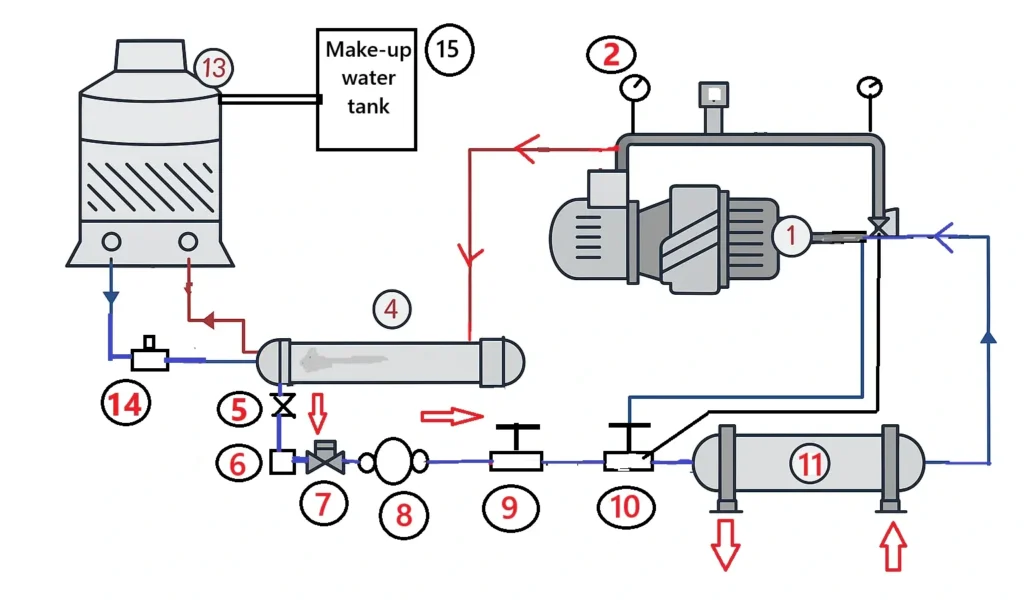

This is a proper picture of how an air cooled chiller works. In The picture

- Compressor

- High pressure gauge

- High/Low pressure protector (when the pressure in the compressor is too high it turn off the compressor)

- Condenser

- Shut off valve

- Filter dryer

- Shut off valve

- Liquid mirror

- Solenoid valve

- Expansion valve

- Evaporator

- Low pressure gauge

- Cooling tower

- Pump

- Make-up water tank.

Close loop:

As you can see in the picture, Low-pressure refrigerant enters the compressor and it compresses the refrigerant gas. As a result, Superheated high-pressure refrigerant gas comes out through the Pressure Gauge and because of that, we can check the pressure of the refrigerant. If any technical fault or any leakage issue happens. Then, by watching the pressure gauge, we can identify these kinds of issues.

Through the high/low pressure gauge (When the pressure in the compressor is too high it turns off the compressor and when the pressure is too low it turns off the system to prevent frizzing and compressor failure issues.) this superheated, high-pressure refrigerant gas goes to the Condenser.

You can see in the picture that chilled water is coming to the condenser from the cooling tower. Here, heat exchange happens and because of condensation, refrigerant gas turns into a cold liquid form.

Then this High-pressure cold liquid refrigerant moves to the Evaporator Through the shut-off valve, Filter dryer, liquid mirror, Solenoid valve, and Expansion Valve.

Shut off valve: With this valve, we can stop the refrigerant flow in the system. This valve is important for maintenance work. If leakage issues happen, during parts changing and for any adjustment shut-off valve is required.

Filter dryer: It filters the liquid refrigerant and removes the moisture from it.

liquid mirror: it is a transparent glass on the system line for the visual inspection of refrigerant flow/moisture flow.

Solenoid valve: It is an electrically operated valve. It controls refrigerant flow to manage the cooling cycles and ensure energy efficiency.

Expansion Valve: The expansion valve expands the cold liquid refrigerant gas. Because of this, the pressure and temperature become much lower.

After passing the expansion valve, the cold liquid refrigerant moves to the evaporator.

Under this thing, there is a heat exchanger coil, which is called an evaporator. See the picture below for more clarity.

So the hot water from the building enters the evaporator. Here through the heat exchanger refrigerant absorbs the heat from the water and becomes low pressure gas. This low-pressure gas moves to the compressor again and this is how this process runs continuously.

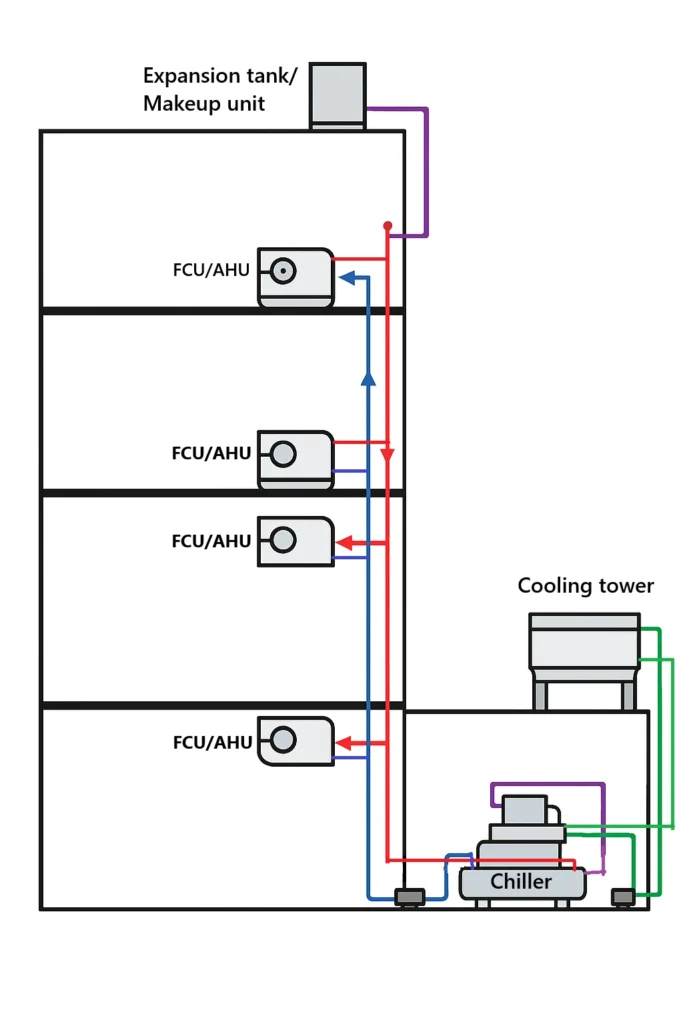

So, the hot water from the building gets cooled down in the evaporator. And this chilled water (6°C) moves to the cooling coil of FCU/AHU (Building load). Where through the heat exchange, our place gets cold and the water gets hot (12°C)again, through the return pipeline this 12°C water moves to the evaporator, where it gets chilled (6°C) and moves to the FCU again. This is how this process works.

In the picture, the chilled water (6°C) from the chiller is moving to the FCU and AHU. After the heat exchange, the room gets cold and the water of the system becomes hot(12°C). Through the return pipeline, this hot water (12°C) moves to the evaporator of the chiller. Then the cold water from the cooling tower moves to the evaporator and the system water becomes chilled (6°C). This is how the evaporator constantly makes the system water chilled (6°C).

Advantages of water-cooled chiller:

1. Less electricity consumption. (Highly energy efficient)

2. Long service life

3. High cooling capacity

Disadvantages of water-cooled chiller:

1. High cost

2. Require more installation time and maintenance cost compared to air cooled chillers.

3. You need to use the basement or other building space for it.

4. Required a large space (Plant room) for the Extra pump, water treatment, cooling tower and extra pipe.