Why VRF system no longer permitted for US Air Force facilities

I wanted to write a blog about why VRF systems are no longer permitted in US Air Force facilities and army construction buildings. We always say how wonderful it is to have VRF in your commercial and residential space. Then why did the US Army refuse to accept VRF in its place?

When a VRF system has a leakage issue, refrigerant gas can escape through the leak. When refrigerant gas spreads into a room, people may experience difficulty breathing. Also addressing and fixing the issue is always challenging.

Many people might be confused about the safety issues with VRF systems. However, there are specific reasons behind this decision. Here, I will explain everything with a proper solution.

Due to security reasons, they no longer allow VRF/VRV systems in their spaces. However, the NAVY still permits VRF/VRV systems if installed while maintaining ASHRAE safety standards.

Officially, they provide three reasons for this decision:

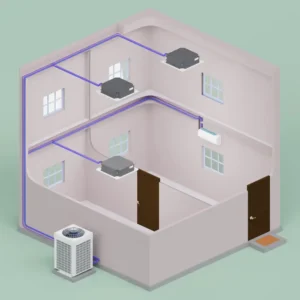

- Concern of Refrigerant Concentration: As we know the refrigerant pipe are install inside the buildings usually over the floor spaces. A typically sized VRF system contains enough R410A refrigerant that can asphyxiate available people in your system in the event of a refrigerant leak.

- Long Refrigerant Runs: Long refrigerant lines are common with VRF systems, and these lines are often branched out. A refrigerant leak would be difficult to locate and, once found, very challenging to repair due to other piping and ductwork installed in dropped ceilings.

- VRF Systems have it’s own control systems. These closed systems are not permitted per UFC 3-410-02 Lonworks ® Direct Digital Control (DDC) for HVAC and other Local Building System, according to UFC 3-410-02 Lonworks® guidelines (with Change 1), it’s recommended to use open DDC (Direct Digital Control) systems. open DDC system allows any qualified professional to easily modify, operate, upgrade, and perform maintenance work on the system.”

US Army Corp Engineers directive (VRF no longer used in military)

As I described, refrigerant gas leakage and repair issues, along with the open DDC system requirements, are the main reasons the US Army does not allow VRF systems in their spaces.

What happens when you inhale Refrigerant Gas:

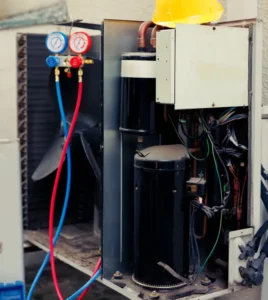

VRF systems use common refrigerants like R410A. Inhaling refrigerant gas can cause headaches and discomfort, but it is not as harmful as inhaling carbon monoxide. Although inhaling refrigerant gas is harmful to your health, it is not extremely dangerous. You will not die from inhaling refrigerant gas.

The real problem is that refrigerant gas is denser than the oxygen in your space. When it spreads out, it displaces the oxygen, making it difficult to breathe properly. This is the most significant negative side effect of refrigerant gas leakage.

If you follow ASHRAE safety standards, you must have a fresh air supply in your commercial or residential space. With a fresh air supply, the risk becomes very low. If your space has an exhaust air line, the refrigerant gas will be expelled through the exhaust. This is why you must have a fresh air supply in your space.

Finding & repairing the leakage of Copper pipe:

In my previous blog “Working principle of VRF/VRV installation process” I talked about How hard it is to find a leakage in your system. There are several reasons behind it, Like

*The low-quality installation process. Maximum time the vendors continue the work with inexperienced workers, this is the most common reason behind this.

* And sometimes they want to complete the work so fast, because of this they don’t complete the welding work properly.

* when the copper pipe got physically damage by something.

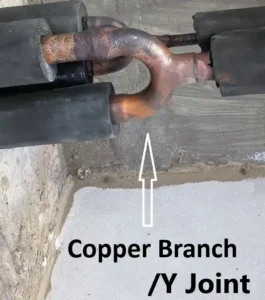

*When the VRF system is operational then it vibrate a little bit due to the very high pressure of the refrigerant. If it has low-quality welding with elbow & Y joints then leakage issues can happen.

* If a VRF/VRV system running for so long, then leakage issues can happen

Once you confirm that your system has a leakage issue then you have to suffer a lot. If the room has ceiling interior work, then you need to open the ceiling in the pipe area. Also, you need to remove the insulation from the copper pipe.

After that, you just need to do the pressure test work. Normally we do 300 psi in the VRF system. After a few hours, you will see the pressure will reduce to 250 psi or 200 psi or less than that. Because of the leakage pressure is going out. This is the time when you need to find the leakage.

It will take 2 to 4 days to find the leakage issue or more than that. This time duration depends on the system length or how critical the pipe work is.

Example: In 2023, I faced a horrible experience with a leakage issue. It was a Midea 500-Ton VRF system in a shopping mall. We proceeded with copper installation work with the insulation, but only the spaces where we connected two copper pipes, or where there were copper Y joints and elbows, remained uninsulated for welding purposes.

After completing the pressure test, we finished the remaining insulation, which is a regular process. However, in that project, we spent four days trying to find the leakage in the system without success. We then thought that there might be a leakage somewhere in the middle of the copper pipe. So, we removed all the insulation from the copper pipes and began the leakage-finding process again. On the second day, we found it. During this period, we faced significant pressure from our client, and it took an additional eight days to meet our work schedule.

This issue happened due to low-quality materials. Make sure you choose the perfect materials for your project.

During this leakage finding and fixing work, your project duration may be extended, and you will face client pressure. To avoid this, monitor the vendor/contractor work quality, especially the welding work.

However in a running system, there are other issues you need to worry about. As I say to fix the repairing issue if needed you need to remove the ceiling and insulation for your system. The most irritating thing is if system leakage repair work is ongoing in your office space then employees can’t continue the office work properly & if the issue is more serious then you need to off your office work until the problem gets solve. And it costs very high to repair those issues.

Maintenance:

Apart from this, there are many maintenance issues such as indoor unit pump motor issues, water level sensor issues, indoor unit PCB, outdoor unit main PCB, outdoor unit power PCB, rectifier, and thermostat issues. These parts can be damaged, and the maintenance team may need to replace them. If you encounter any noise issues during indoor unit operation, it may indicate a defective FCU motor. The maintenance team will need to clean the fan motor and use the required lubricant or replace the fan motor to solve the issue.

VRF maintenance is more costly than regular unitary systems or split air conditioners.

Direct Digital Control (DDC) Permit issue:

Direct Digital Control (DDC) is a system that allows any professional to easily modify, operate, upgrade, and perform maintenance work on the system.

But VRF systems come with proprietary controls and it control & maintained by their specific rules or commands, Which is not similar to standard DDC systems. That is why you can’t easily modify, operate, upgrade & perform maintenance work like another air-conditioner system. Because you need to follow specific rules to install & operate the VRF system.

Basically, those are the reason the US Army discourage the VRF system in their space.

Should you still consider VRF system:

After reading about these issues and problems, you may wonder whether to consider a VRF/VRV system for your commercial or residential space. Don’t compare your residential or commercial space with military construction. Military buildings have serious security concerns about their apace, A spay can intentionally make a leakage in their system. Unlike commercial and residential spaces, military spaces have special security requirements. Even the US people like to use the VFR system in their commercial buildings. Trust me, you should choose a VRF system for your commercial and residential spaces. This would be the best decision. Variable Refrigerant Flow (VRF) is designed for this type of commercial and residential space.

There are 157 countries in the world, and no one else has a problem with the VRF system like the United States. If you install VRF systems following ASHRAE safety standards, you will not face any significant problems. The US Army made this decision because they have the resources to invest in chillers or other air conditioning systems, which are more reliable than VRF. However, the US Navy still allows VRF systems if installed according to ASHRAE safety standards.

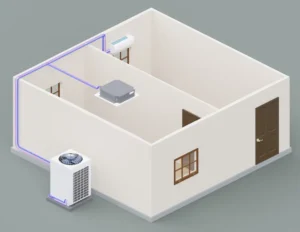

VRF means Variable Refrigerant Flow. In VRF unlike the Split/Unitary system you can use several indoor units in one system. So according to your requirements & indoor unit capacity, the refrigerant flow varies on each indoor unit. That’s why it’s called the VRF system.

VRF can provide heat & cool both as per your requirement. It uses common refrigerants like R410A. You get so many options to customize your system, you can install it as per your design.

Although it costs more than the split system, But provides more value like better efficiency and better Life expectancy & also it looks great compared to the split system.

VRF/VRV is very efficient compared to the Split system. Split ac consumes 1.2KW/Ton & VRF/VRV consumes 0.8KW/Ton, so I hope the difference is clearer to you. Although it costs higher than the Split ac. But its life expectancy is 15 years, while the split AC life expectancy is 10 years.

Solution | Electricity consumption | Life expectancy | Investing | Project duration |

VRF/VRV | 0.8KW/Ton | 15 years | Average | Short |

Split AC | 1.2KW/Ton | 10 years | Low | Shortest |

You can customize a lot as per your requirements. Unlike Split AC you can use multiple indoor units in one system. You can select cassette type IDU (Indoor unit), duct type, FCU, etc. The complete work will be complete as per your design. Because you don’t have enough space on the floor to install an outdoor unit in the floor, you can easily install it on the rooftop, and then by using Cooper riser you can connect it to the floor. If needed During the installation process if you want you can change the pipe rotation or indoor location.

You also have many options to control your room temp. for a duct-type indoor unit, you should use a thermostat, for cassette type indoor unit you can control your indoor unit by remote. You can also use CCM to control the whole system at once. There is another way to control your VRF system, by using a Wi-Fi controlling system you can control your indoor unit with your phone.

So, although the US Army no longer allows VRF systems in their space. You don’t need to worry about it. You can easily install this system by following ASHRAY safety standards.